www.industry-vietnam.com

02

'09

Written on Modified on

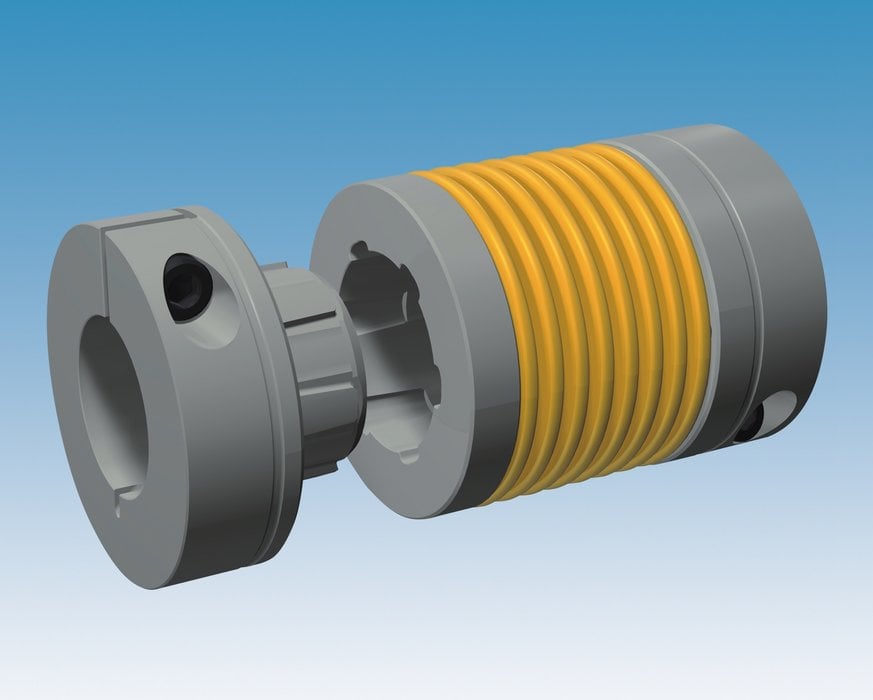

primeflex - The new top-class steel bellows coupling

primeflex stands for innovative technology oriented towards future applications at an exceptionally economic price. In contrast to other plug-in bellows couplings, it can be dismantled safely without putting the steel bellows at risk even after longer operating times.

At first glance all steel bellows couplings seem alike; but on taking a closer look, we find substantial differences in the technical details. The construction, structure and manufacturing quality of the steel bellows are the main factors for operational safety, reliability, service lifetime, misalignment capability and functional safety of the entire coupling. Further quality-influencing factors are the connection of the bellows to the hub components and the shaft-hub connections. They influence, for example, the transmittable torque and the coupling running characteristics decisively.

The new primeflex unites the collective know-how of one of the leading manufacturers for backlash-free shaft couplings. mayr® power transmission has been developing and manufacturing such couplings for several decades. Thanks to its years of experience in the field, the company knows all the demands placed on electrical power transmission, and has developed new unique features to enhance reliability and facilitate operation.

The backlash-free primeflex can be plugged in for easy installation and disassembly. It can be dismantled safely without putting the steel bellows at risk even after longer operating times. Herein lies one of the decisive technical advantages. On many other plug-in steel bellows couplings, there is a risk of damaging or even destroying the steel bellows when loosening the plug-in connection (tribo-corrosion effect on the conic hub). primeflex features specific material and geometry to fix this problem.

The extremely compact and high performance-density primeflex can be mounted easily onto the shafts via clamping or shrink disk connections. Another outstanding performance characteristic is the excellent misalignment capability of the new cost-effective steel bellows coupling. It compensates for axial, radial and angular shaft misalignments. The torque is transmitted via frictional locking or via frictional and positive locking. Furthermore, the internal mechanism integrates a stop in order to avoid bellows damages which can occur with excessive mounting pressure.

We currently offer three sizes, with nominal torques from 24 to 120 Nm. In the field of shaft couplings, mayr® power transmission has specialised in backlash-free couplings in servo power transmission services. With its steel bellows, elastomer and disk pack couplings, the company is able to provide the three most common constructional designs for this power transmission segment.

Steel bellows coupling are most often utilised to enable a power transmission between a motor and a reducer or a shaft, while allowing a correction of misalignment. The Main applications include all kind of machines (food processing, machine-tool, packaging…).

The new primeflex unites the collective know-how of one of the leading manufacturers for backlash-free shaft couplings. mayr® power transmission has been developing and manufacturing such couplings for several decades. Thanks to its years of experience in the field, the company knows all the demands placed on electrical power transmission, and has developed new unique features to enhance reliability and facilitate operation.

The backlash-free primeflex can be plugged in for easy installation and disassembly. It can be dismantled safely without putting the steel bellows at risk even after longer operating times. Herein lies one of the decisive technical advantages. On many other plug-in steel bellows couplings, there is a risk of damaging or even destroying the steel bellows when loosening the plug-in connection (tribo-corrosion effect on the conic hub). primeflex features specific material and geometry to fix this problem.

The extremely compact and high performance-density primeflex can be mounted easily onto the shafts via clamping or shrink disk connections. Another outstanding performance characteristic is the excellent misalignment capability of the new cost-effective steel bellows coupling. It compensates for axial, radial and angular shaft misalignments. The torque is transmitted via frictional locking or via frictional and positive locking. Furthermore, the internal mechanism integrates a stop in order to avoid bellows damages which can occur with excessive mounting pressure.

We currently offer three sizes, with nominal torques from 24 to 120 Nm. In the field of shaft couplings, mayr® power transmission has specialised in backlash-free couplings in servo power transmission services. With its steel bellows, elastomer and disk pack couplings, the company is able to provide the three most common constructional designs for this power transmission segment.

Steel bellows coupling are most often utilised to enable a power transmission between a motor and a reducer or a shaft, while allowing a correction of misalignment. The Main applications include all kind of machines (food processing, machine-tool, packaging…).