www.industry-vietnam.com

07

'09

Written on Modified on

Major irrigation projects from Imperia to Venice

In 2008, in the Italian Triveneto region, from Imperia to Venice, more than 25,000 m of FLOWTITE glass-fibre reinforced plastic (GRP) piping was laid as part of irrigation projects. The construction projects not only helped to preserve the environment, they also considerably increased the levels of agricultural productivity in the region. As irrigation affects the water table due to the wells dug, most of the water currently used comes from mountain streams or rivers. This avoids lowering the water table and cuts project costs.

The clients for the irrigation installations were local consortiums, in which the farmers concerned have holdings, together with other entities. The projects are partly supported by local improvement grants and they are supervised directly by the State. Cost effectiveness was the key factor for the consortiums when selecting the piping supplier. The lowest possible costs, combined with high quality, good piping characteristics and ideal installation properties made GRP piping an ideal candidate for this type of use.

From a geographical standpoint, and in concrete terms, the fact of piping surface water in from the mountainous regions for irrigation purposes did not present any problems, as the Triveneto region lies in the Alpine catchment area. This ensures a constant water supply for irrigation.

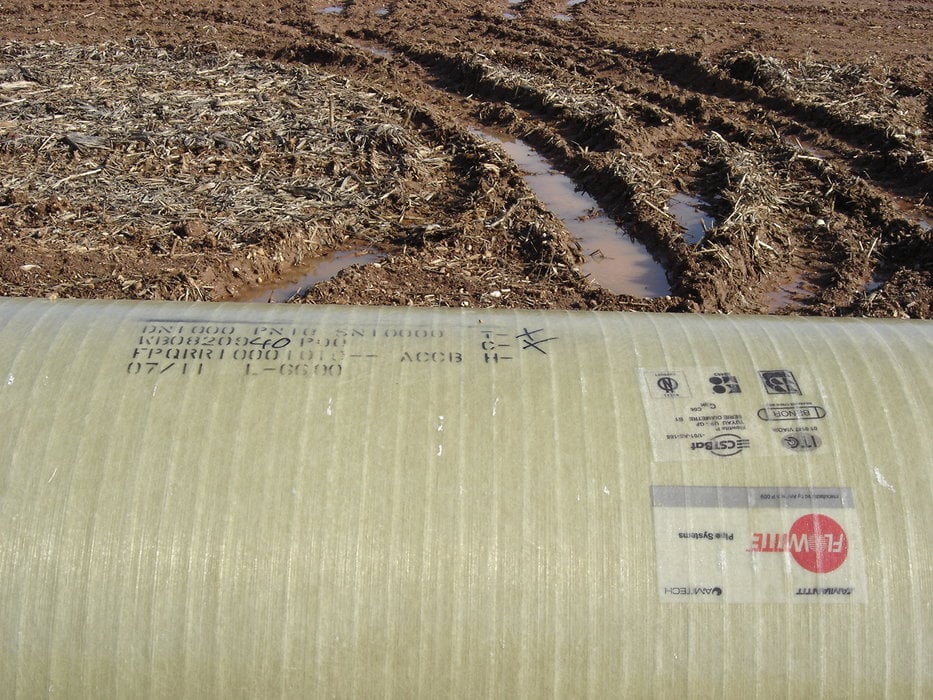

Production and supply of the FLOWTITE GRP pipes, which are available worldwide and compatible with all standards, was carried out in close cooperation by the “AMITECH Germany“ and “AMITECH Spain“ Companies; both of them are subsidiaries of the Amiantit Group with its worldwide activities. For the “Campigo“ project, 7,000 metres of ND 1,000 mm diameter GRP piping with an NP 10 pressure rating and an NS 10,000 rigidity class were used. For the “Pedemontana“ project, 10,000 m of ND 350 to ND 700 piping were used, while the “Nervesa della Battaglia“ project involved laying 9,000 m of ND 700 mm FLOWTITE GRP piping with an NP 16 pressure rating and an NS 10,000 rigidity class.

Over and above the excellent chemical characteristics, above all the physical properties of the continuously rolled glass-fibre reinforced plastic piping – or “GRP“ piping for short – were a major factor in the decision to use them in the Italian projects mentioned above. Whether they are laid underground or on the surface, the laying times are about 50% shorter than with many conventional types of piping. GRP piping is lighter and it has been used with REKA type connecting fittings, amongst others, for 50 years now, which makes it a thoroughly tried and tested technology. The piping stands up to UV radiation, and thanks to its extremely smooth inner surface, there are hardly any deposits, even in the case of very slight drops.

From a geographical standpoint, and in concrete terms, the fact of piping surface water in from the mountainous regions for irrigation purposes did not present any problems, as the Triveneto region lies in the Alpine catchment area. This ensures a constant water supply for irrigation.

Production and supply of the FLOWTITE GRP pipes, which are available worldwide and compatible with all standards, was carried out in close cooperation by the “AMITECH Germany“ and “AMITECH Spain“ Companies; both of them are subsidiaries of the Amiantit Group with its worldwide activities. For the “Campigo“ project, 7,000 metres of ND 1,000 mm diameter GRP piping with an NP 10 pressure rating and an NS 10,000 rigidity class were used. For the “Pedemontana“ project, 10,000 m of ND 350 to ND 700 piping were used, while the “Nervesa della Battaglia“ project involved laying 9,000 m of ND 700 mm FLOWTITE GRP piping with an NP 16 pressure rating and an NS 10,000 rigidity class.

Over and above the excellent chemical characteristics, above all the physical properties of the continuously rolled glass-fibre reinforced plastic piping – or “GRP“ piping for short – were a major factor in the decision to use them in the Italian projects mentioned above. Whether they are laid underground or on the surface, the laying times are about 50% shorter than with many conventional types of piping. GRP piping is lighter and it has been used with REKA type connecting fittings, amongst others, for 50 years now, which makes it a thoroughly tried and tested technology. The piping stands up to UV radiation, and thanks to its extremely smooth inner surface, there are hardly any deposits, even in the case of very slight drops.