www.industry-vietnam.com

09

'08

Written on Modified on

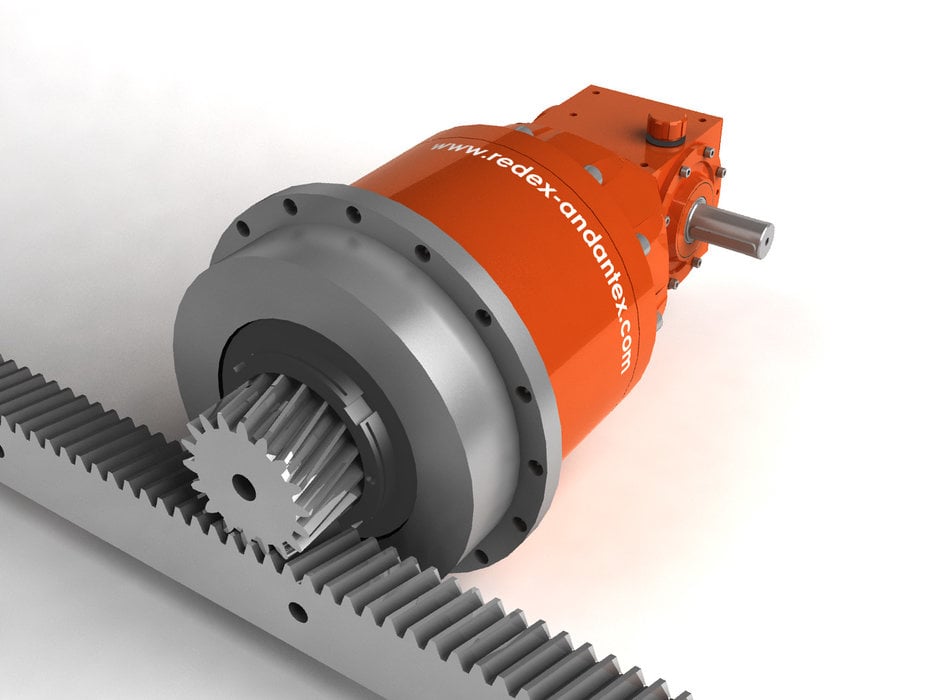

KRP+

This planetary reduction gear for rack and pinion applications offers exceptional rigidity characteristics, in particular through the one-piece output pinion technology invented by REDEX. It provides unrivalled radial rigidity (accounting for up to 60% of overall rigidity).

REDEX ANDANTEX confirms its benchmark position in the field of high-performance rack and pinion drives with its KRP+ specialized reduction gear range.

The KRP+ is exceptionally rigid, necessary for highly-demanding rack and pinion drive applications. KRP+ is available in the 6 standard universal sizes. For size 6, torsional rigidity is 5,500,000 Nm/rad, while radial rigidity is 960,000 N/mm and axial rigidity is 6,194,000 N/mm, substantially exceeding market standards.

The rigidity of KRP+ is a consequence of its design with integrated output pinion and reinforced output bearing. The output pinions are machined to the same diameter as the shafts, giving the optimum compromise between transmissible torque and rigidity at the rack.

The output bearing consists of two preloaded and substantially oversized angular contact roller bearings. This construction enables the bearing to support the pinion as close as possible to the force, as only the thickness of the fastening nut separates the pinion from the output bearing.

This design considerably reduces radial bending, which is responsible for 60% of overall distortion but is nevertheless still poorly handled by existing systems.

The result is increased dynamic precision thanks to its capacity to displace heavier loads at higher speed. Its performance in terms of stiffness combined with its low inertia enable higher accelerations (up to 25 m/s2). As a consequence, the resonance frequencies of the drive systems in which it is incorporated can be raised significantly.

KRP+ can be used singly or in pairs. In the second case, preloading enables zero backlash. This solution is particularly suited to high-precision systems.

The KRP+ is exceptionally rigid, necessary for highly-demanding rack and pinion drive applications. KRP+ is available in the 6 standard universal sizes. For size 6, torsional rigidity is 5,500,000 Nm/rad, while radial rigidity is 960,000 N/mm and axial rigidity is 6,194,000 N/mm, substantially exceeding market standards.

The rigidity of KRP+ is a consequence of its design with integrated output pinion and reinforced output bearing. The output pinions are machined to the same diameter as the shafts, giving the optimum compromise between transmissible torque and rigidity at the rack.

The output bearing consists of two preloaded and substantially oversized angular contact roller bearings. This construction enables the bearing to support the pinion as close as possible to the force, as only the thickness of the fastening nut separates the pinion from the output bearing.

This design considerably reduces radial bending, which is responsible for 60% of overall distortion but is nevertheless still poorly handled by existing systems.

The result is increased dynamic precision thanks to its capacity to displace heavier loads at higher speed. Its performance in terms of stiffness combined with its low inertia enable higher accelerations (up to 25 m/s2). As a consequence, the resonance frequencies of the drive systems in which it is incorporated can be raised significantly.

KRP+ can be used singly or in pairs. In the second case, preloading enables zero backlash. This solution is particularly suited to high-precision systems.